CBN Minerals

CBN minerals for high-performance grinding and cutting.

Products

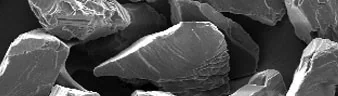

CBN-90

WIDENTA

A black, friable CBN abrasive offering excellent micro-fracture behavior for superior surface finishing and efficient high-speed machining.

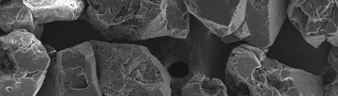

CBN-130

WIDENTA

An amber-transparent CBN material balancing strength and fracture behavior for versatile grinding across ferrous materials.

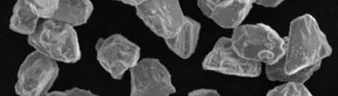

CBN-150

WIDENTA

A black CBN grade combining moderate toughness with good thermal stability, balancing cutting performance and tool life.

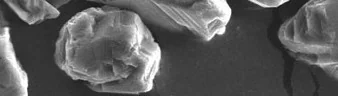

CBN-180

WIDENTA

A deep brown, high-toughness CBN material featuring superior self-sharpening and high thermal conductivity for aggressive grinding applications.

CBN-190

WIDENTA

A black CBN abrasive with extreme toughness and high thermal resistance, designed for interrupted and high-pressure grinding conditions.

Overview

Cubic Boron Nitride (CBN) minerals are designed for the toughest grinding and cutting tasks, especially on hardened steels. With outstanding hardness, thermal stability up to 1,400°C, and low chemical reactivity, CBN ensures long tool life and precise results in automotive, aerospace, and bearing manufacturing. Controlled friability and engineered grain structures maintain sharpness and efficiency throughout demanding operations.

Highlights

Exceptional Hardness

Second only to diamond (Knoop hardness 4,500 HV) for machining hardened steels (>45 HRC).

Thermal Stability

Withstands 1,400°C without phase degradation—ideal for dry/high-speed grinding.

Features

Low Chemical Reactivity

Inert with iron-based alloys, preventing tool wear when grinding ferrous metals.

Controlled Friability

Engineered grain fracture patterns maintain sharp cutting edges longer than alumina.