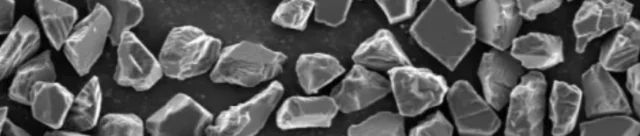

Electroless Nickel Coated Diamonds

Nickel-coated diamonds for enhanced bond retention and tool life.

Products

Electroless Nickel Coating Diamond Mesh Size

WIDENTA

Electroless Ni-coated synthetic diamonds sorted into mesh sizes offer consistent cutting, high durability, and enhanced bond retention for rough grinding and shaping operations.

Overview

Electroless Nickel Coated Diamonds feature high-purity synthetic diamond grains uniformly plated with a nickel-phosphorus alloy. This coating improves adhesion in resin and metal bonds, enhances heat dissipation, and extends tool life under demanding conditions. The result is superior performance in grinding, cutting, and finishing applications across industries such as composites, stone, and advanced manufacturing.

Highlights

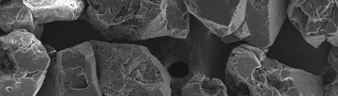

Superior Bond Retention

Nickel coating provides a rugged surface for enhanced grip in resin and metal bonds.

Improved Heat Dissipation

Reduces thermal degradation during high-speed grinding and cutting.

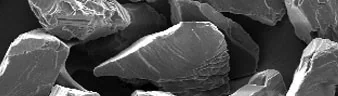

Enhanced Surface Roughness

Roughened diamond surfaces improve mechanical interlocking in bonding systems.

High Durability

Supports longer tool lifespan even under extreme loads.

Better Dispersion

Minimized particle agglomeration ensures even distribution in composite materials.

Features

Uniform Electroless Ni–P Coating

Complete and even nickel-phosphorus encapsulation for predictable performance.

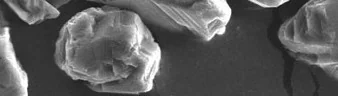

High-Purity Diamond Cores

Manufactured from top-grade HPHT synthetic diamonds for consistent quality.

Corrosion-Resistant Alloy

Non-magnetic and oxidation-resistant nickel-phosphorus layer protects the core material.

Available in Mesh and Micron Sizes

Customizable particle size range for different application requirements.

High Strength and Toughness

Maintains structural integrity under heavy industrial use.