Friable Diamonds

Self-sharpening synthetic diamonds for fast, fine grinding.

Products

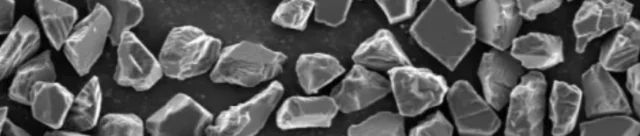

Friable Diamond - WD-S

WIDENTA

WD-S is a high-grade friable diamond with micron-sized grains, engineered for precision applications requiring exceptional surface finishes. Its superior friability and rough crystal surfaces ensure excellent bond retention, high cutting rates, and minimal heat generation, making it ideal for fine grinding and polishing.

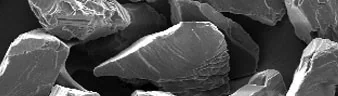

Friable Diamond - WD-X

WIDENTA

WD-X balances aggressive cutting performance with extended tool life. Its irregular, sharp-edged crystals with low impurity content and excellent self-sharpening ability make it especially suited for grinding very hard materials like tungsten carbide with precision and efficiency.

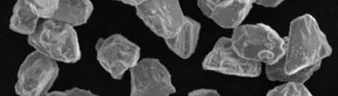

Friable Diamond - WD-F

WIDENTA

WD-F offers a cost-effective solution for high-efficiency grinding. Featuring an irregular shape and strong self-sharpening properties, it is designed for users seeking high material removal rates and reliable performance without compromising production budgets.

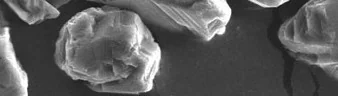

Friable Diamond - WD-FS

WIDENTA

WD-FS is a polycrystalline friable diamond optimized for dry grinding. Its microcrystalline structure enables continuous exposure of sharp cutting edges during operation, ensuring efficient, high-speed grinding without the need for coolant.

Overview

Friable Diamonds are synthetic abrasives with engineered microstructures that promote continuous self-sharpening during use. This results in fast material removal, superior surface finishes, and consistent performance on hard, brittle materials like tungsten carbide, ceramics, and glass. Their efficient heat management and sharpness retention make them ideal for precision grinding and tool manufacturing.

Highlights

Engineered Friability

Controlled microfracturing ensures consistent cutting performance and tool renewal.

Superior Surface Finish

Achieves fine surface finishes even at high material removal rates.

Material Versatility

Optimized for hard-to-machine materials like carbide, ceramics, and glass.

Features

Self-sharpening Structure

Maintains sharp cutting edges throughout the grinding process.

Efficient Heat Management

Minimizes heat buildup, reducing risk of material damage.