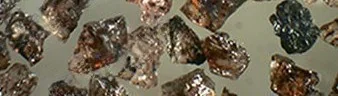

Semi-friable fused Alumina

Self-sharpening semi-friable alumina for enhanced cutting and tool life.

Overview

Semi-friable fused alumina is produced by fusing bauxite and Bayer-alumina with additives, resulting in grains that balance hardness and controlled breakdown. Special treatments like calcining, heat treatment, and ceramic coating further enhance performance, making it ideal for abrasive applications requiring self-sharpening and durability.

Features

Calcined at 1050 centigrade

To enhance the performance of grains even further, standard brown fused alumina undergoes a ceramic coating on the surface following a heat treatment at 1350 degrees Celsius through open annealing. This process is denoted as "HTCC."

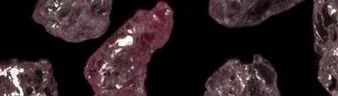

Heat treated at 1350 centigrade

To withstand high-stress working conditions, semi-friable fused alumina undergoes a heat treatment at 1350 degrees Celsius through open annealing. This process results in a color transformation from light brown to light blue. The treatment is specifically designed to rejuvenate the majority of crystal imperfections and alter the crystal lattice by introducing foreign oxides. Consequently, the grains experience improvements in both cutting quality and tool life. This treatment is denoted as "HT."

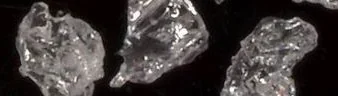

Ceramic Coating

To enhance the bonding characteristics of grains, semi-friable fused alumina can undergo a surface modification through ceramic coating. This coating facilitates the creation of a ligament between the grains and resin. Simultaneously, the heat treatment applied during the process serves to modify the crystal structure, leading to increased toughness in the grains. This treatment is identified as "CC."

Heat treated at 1350 centigrade and Ceramic Coated

To enhance the performance of grains even further, semi-friable fused alumina undergoes a surface modification through ceramic coating following a heat treatment at 1350 degrees Celsius through open annealing. This treatment is designated as "HTCC."

Specifications

| Key | Value |

|---|---|

| F8–F1200 (FEPA standard 42, GB/T 2481), customizable to JIS/ANSI/customer | |

| Custom shapes, including blocky and sharp shapes, can be accommodated upon special customer request | |

| 97.60% | |

| 1.35% | |

| 0.45% | |

| 0.10% | |

| 0.20% | |

| 0.30% | |

| Increases toughness and tool life | |

| Improves tool life and cutting quality | |

| Enhances bonding and toughness | |

| Maximizes performance and durability |

Similar

Ceramic Corundum

WIDENTA

Engineered ceramic corundum for high-performance grinding and wear resistance.

High Purity Corundum

WIDENTA

Ultra-high purity corundum for critical abrasive and polishing applications.

Zirconia Alumina

WIDENTA

Eutectic alloy of alumina and zirconia for aggressive grinding and steel conditioning.

Substandard Regular Brown Fused Alumina

WIDENTA

Cost-effective brown fused alumina for general grinding and blasting.

Substandard Semi-Friable Fused Alumina

WIDENTA

Budget-friendly semi-friable fused alumina for medium-duty grinding and finishing.

Substandard TC Monocrystalline Fused Alumina

WIDENTA

Economical monocrystalline fused alumina for DIY and non-critical grinding.

Super TC Monocrystalline Fused Alumina

WIDENTA

High-performance monocrystalline alumina for demanding grinding applications.

TC Monocrystalline Fused Alumina

WIDENTA

Premium monocrystalline fused alumina for precision grinding and finishing.