Zirconia Alumina

Eutectic alloy of alumina and zirconia for aggressive grinding and steel conditioning.

Products

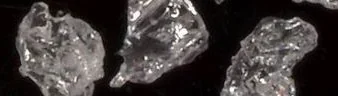

Zirconia Alumina - ZACT40

WIDENTA

Zirconia Alumina abrasive with optimized titanium content (0.3%) for balanced toughness and sharpness. Features fine microcrystal fracture properties for outstanding cutting ability and rapid stock removal in stainless steel and high alloy steel applications.

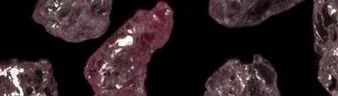

Zirconia Alumina - ZATT40

WIDENTA

High-titanium variant (1.5% TiO₂) of zirconia alumina with enhanced toughness for aggressive stock removal. Maintains the Al₂O₃-ZrO₂ eutectic advantages while offering increased durability in heavy grinding operations.

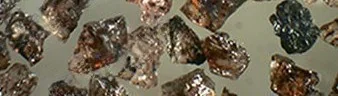

Zirconia Alumina - ZAF25

WIDENTA

The densest and toughest grade of zirconia alumina abrasive (74% Al₂O₃, 25% ZrO₂) with exceptional wear resistance. Features a unique eutectic crystalline structure ideal for foundry-type grinding wheels and steel conditioning applications.

Overview

Zirconia alumina is a fused eutectic alloy, combining alumina and zirconia for outstanding cutting ability, toughness, and rapid stock removal. Its customizable chemistry and particle size distribution make it suitable for stainless steel, high alloy steels, and demanding grinding systems, ensuring long tool life and high efficiency.

Highlights

Outstanding Cutting Ability

Fine microcrystal fracture properties for rapid stock removal and long tool life.

Customizable Toughness

Titanium content can be adjusted for optimal balance of toughness and sharpness.

Versatile Applications

Ideal for stainless steel, high alloy steels, and low thermal-releasing grinding systems.

Features

Eutectic Alloy Structure

Fusion of alumina and zirconia at high temperature for superior properties.

Particle Size Distribution

Available in F8–F220, compliant with FEPA, JIS, ANSI, and GB/T standards.

Customizable Chemistry

Compositions and PSD can be tailored to customer requirements.

Similar

Ceramic Corundum

WIDENTA

Engineered ceramic corundum for high-performance grinding and wear resistance.

High Purity Corundum

WIDENTA

Ultra-high purity corundum for critical abrasive and polishing applications.

Semi-friable fused Alumina

WIDENTA

Self-sharpening semi-friable alumina for enhanced cutting and tool life.

Substandard Regular Brown Fused Alumina

WIDENTA

Cost-effective brown fused alumina for general grinding and blasting.

Substandard Semi-Friable Fused Alumina

WIDENTA

Budget-friendly semi-friable fused alumina for medium-duty grinding and finishing.

Substandard TC Monocrystalline Fused Alumina

WIDENTA

Economical monocrystalline fused alumina for DIY and non-critical grinding.

Super TC Monocrystalline Fused Alumina

WIDENTA

High-performance monocrystalline alumina for demanding grinding applications.

TC Monocrystalline Fused Alumina

WIDENTA

Premium monocrystalline fused alumina for precision grinding and finishing.