Minerals for Superabrasives

Premium minerals for precision and durability in superabrasive uses.

Products

Overview

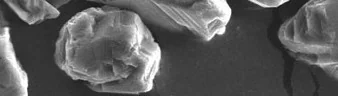

Our Minerals for Superabrasives are engineered to deliver exceptional precision, durability, and consistency for demanding industrial applications. Featuring high-purity CBN and diamond variants—including monocrystal, friable, and nickel-coated options—these minerals are optimized for maximum material removal, extended tool life, and repeatable results in high-tolerance environments such as aerospace, automotive, and electronics manufacturing.

Highlights

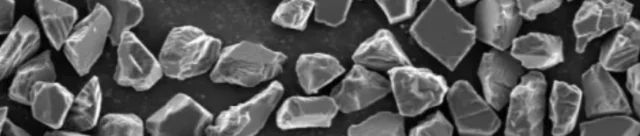

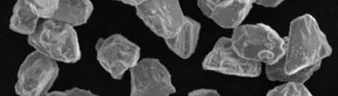

Premium Superabrasive Minerals

High-purity CBN and diamond minerals for precision grinding, cutting, and finishing applications.

Specialized Diamond Variants

Monocrystal, friable, and electroless nickel-coated diamonds for tailored performance needs.

Engineered for Efficiency

Optimized crystal structures for maximum material removal and extended tool life.

Industry-Leading Consistency

Uniform particle size distribution (PSD) for repeatable results in high-tolerance applications.

Features

Thermal Shock Resistance

CBN grains stable up to 1,400°C—ideal for dry grinding aerospace alloys.

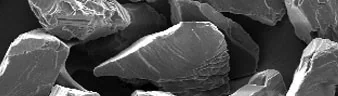

Fracture-Controlled Grains

Friable diamonds micro-engineered to self-sharpen during use (resin bond applications).

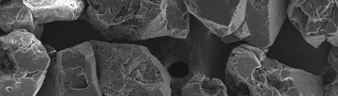

Metallurgical Bond Boost

Electroless nickel coating increases abrasive retention by 40% in sintered tools.

Optical-Grade Purity

Type IIa diamonds with <5ppb nitrogen for semiconductor wafer processing.