Profile Grinding Wheels - External Cylindrical Grinders

WIDENTA

Profile grinding wheels for external cylindrical grinding machines.

Grinding tools for external cylindrical grinders

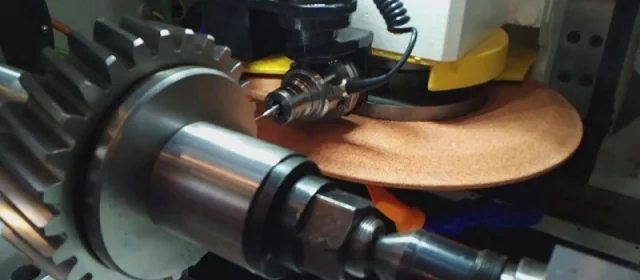

Profile grinding is generally employed to grind precision moulds, gears, and other objects with complicated forms of irregular lines and curves. For custom orders, we fulfill individual development.

Profile grinding wheels for external cylindrical grinding machines.

Straight wheels for external cylindrical grinding operations.

Grinding wheels with two-side recess for specialized cylindrical grinding.

Widenta grinding tools for external cylindrical grinders deliver precision and versatility for complex cylindrical grinding tasks. With customizable solutions and multi-material compatibility, these tools are trusted for high-precision work in demanding industries.

Engineered for complex geometries (gears, molds, curves) with micron-level accuracy (±0.001mm).

Heat-resistant, durable bonds for consistent performance under heavy loads and high RPM.

Tailored grinding wheels (10–600mm diameters) for unique OEM and industrial applications.

Optimized for hardened steel, alloys, and composites with minimal thermal distortion.

Laser-verified abrasive consistency for repeatable finishes (P40–P2000 range).

Reduces workpiece burn, critical for aerospace and medical components.

Balanced cores tested at 12,000 RPM for vibration-free operation.

Bespoke grain types (CBN, diamond) and bonds (resin, hybrid) in 72hr lead time.

Grinding wheels designed for saw sharpening machines to ensure precise and efficient sharpening.

High-performance grinding wheels for gear grinders, ensuring accuracy and durability.

Specialized grinding wheels for rail grinding, designed to maintain and restore rail tracks efficiently.

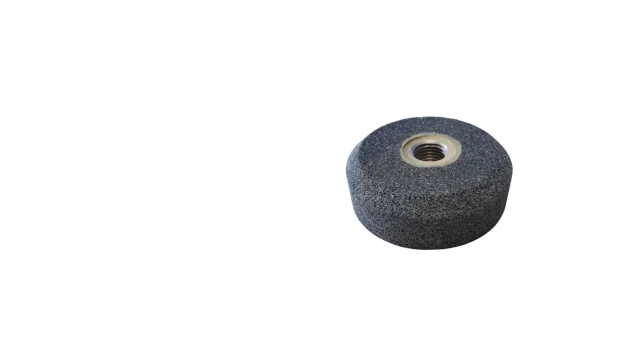

Widenta offers valve grinding wheels for the automotive industry. Regular types of valve grinding wheels are manufactured with M10 and M14 thread. For custom orders we fulfill individual development.