Dish Grinding Wheels - Gear Grinders

WIDENTA

Dish-shaped grinding wheels for gear grinding machines.

High-performance grinding wheels for gear grinders, ensuring accuracy and durability.

Widenta high-performance grinding wheels for gear grinders ensure accuracy and durability in gear manufacturing, with custom-engineered abrasives and industrial-grade durability for every gear grinding challenge.

Delivers micron-level accuracy (±0.002mm) for gears, splines, and complex profiles.

Dish wheels (80–500mm) for gear teeth sharpening; profile wheels for intricate moulds and curves.

Tailored grain types (CBN, diamond) and bonds (vitrified, hybrid) for OEM gear materials.

Vitrified bonds withstand high-RPM grinding (up to 15,000 RPM) without degradation.

Ceramic alumina grains for fast stock removal on hardened steel (HRC 60+).

Open-coat design minimizes heat buildup, preserving gear metallurgy.

Vibration-free operation for noise-sensitive applications (e.g., automotive transmissions).

72-hour lead time for non-standard diameters/profiles (per customer blueprints).

Grinding wheels designed for saw sharpening machines to ensure precise and efficient sharpening.

Specialized grinding wheels for rail grinding, designed to maintain and restore rail tracks efficiently.

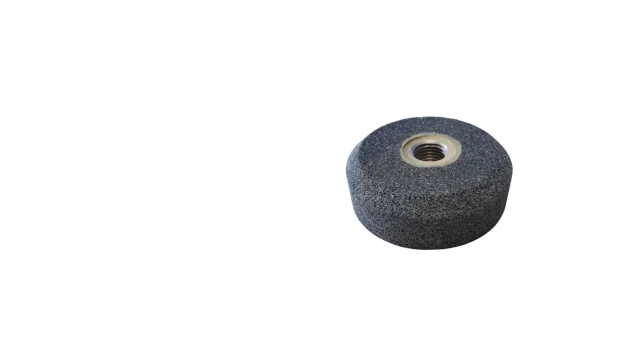

Widenta offers valve grinding wheels for the automotive industry. Regular types of valve grinding wheels are manufactured with M10 and M14 thread. For custom orders we fulfill individual development.