Dish Grinding Wheels - Saw Sharpening Machines

WIDENTA

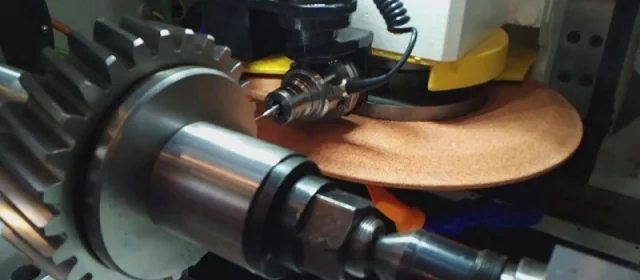

Dish-shaped grinding wheels for saw sharpening machines.

Grinding wheels designed for saw sharpening machines to ensure precise and efficient sharpening.

Widenta grinding wheels for saw sharpening machines are engineered for precise, efficient sharpening of all saw blades and cutting tools, with a wide size range and customizable solutions for every sharpening need.

Engineered for razor-sharp edges on all saw types (circular, band, carbide-tipped) with micron-level consistency.

Dish grinding wheels from 80mm to 500mm diameters to fit industrial and portable sharpening systems.

Tailored abrasive formulations (grit, bond) for specific saw materials (HSS, carbide, bi-metal).

Heat-resistant bonds maintain wheel integrity during high-RPM sharpening operations.

Aluminum oxide or diamond grains arranged for fast material removal without tooth overheating.

Laser-tested for vibration-free operation at up to 3,000 RPM (ISO 6104 certified).

Standardized hubs for seamless integration with Vollmer, Armstrong, and other sharpening machines.

30% longer lifespan than resin-bond wheels in timber processing tests (AbrasiveTech 2024).

High-performance grinding wheels for gear grinders, ensuring accuracy and durability.

Specialized grinding wheels for rail grinding, designed to maintain and restore rail tracks efficiently.

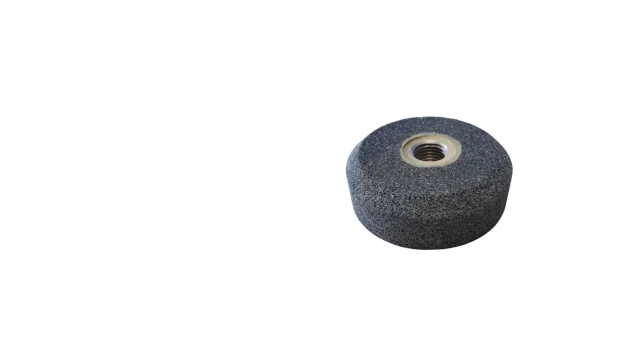

Widenta offers valve grinding wheels for the automotive industry. Regular types of valve grinding wheels are manufactured with M10 and M14 thread. For custom orders we fulfill individual development.